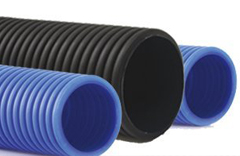

All over the world, it has become a common practice to use over metallic ducts due to the several advantages that they offer. We provide SWC Pipes with better corrosion resistance, better flexibility and resistance to harsh weather conditions. Our pipes also provide better water tightness and are environmentally friendlier than other similar products. Our pipes are available in several different sizes and can also be customized as per specific client requirements.

Single Walled Corrugated Pipes are used as Sheathing Ducts in projects such as bridges, flyovers, offshore platforms, via ducts, tunnels, underpasses etc. Corrosion is the biggest threat to any infrastructure and metallic sheathing ducts in spite of galvanizing invariably corrode very quickly. HDPE SWC sheathing ducts manufactured by us provide superior resistance against such problems and are already being used successfully in various projects globally.

These joints can be easily mounted on the main pipes supplied by us without the use of any custom equipment. More over they are also universally acceptable to ensure that our clients do not incur any additional costs.

Available sizes of HDPE Sheathing Ducts

| Sizes OD/ID | Thickness | Length |

| 50mm / 39 mm | 2mm/2.5mm | 30 Mtrs. |

| 63mm / 50 mm | 2mm/2.5mm | 30 Mtrs. |

| 78mm / 63 mm | 2mm/2.5mm | 30 Mtrs. |

| 92 mm / 75 mm | 2mm/2.5mm | 30 Mtrs. |

| 97 mm / 85 mm | 2mm/2.5mm | 30 Mtrs. |

| 110mm / 95 mm | 2mm/2.5mm | 30 Mtrs. |

| 120mm / 103 mm | 2mm/2.5mm | 6 Mtrs. |

| 125mm / 105 mm | 2mm/2.5mm | 6 Mtrs. |

| 160mm / 136 mm | 2mm/2.5mm | 6 Mtrs. |